Hints & Tips

Top Surfaces To Protect On Data Center Projects

May 29, 2025

Data centers have become one of the fastest growing sectors in construction across North America and particularly in the US, and the numbers back it up. Billions of dollars are already being funneled into these hyperscale facilities, edge computing hubs, and colocation projects across the country. While the contents of these centers are cutting-edge and high-tech, the surfaces throughout are extremely vulnerable during construction. Once finishes start going in, there’s no room for error. That’s why we’re here with the top surfaces at risk on data center jobsites, as well as our top recommendations for keeping these high-value projects protected from day one.

Understanding The Importance Of Temporary Surface Protection In Data Centers

Data centers are the backbone of our digital world, housing critical infrastructure that supports everything from cloud computing to data storage for major corporations. As these facilities continue to grow in scale and complexity, the construction phase only becomes more vital. It’s not just about erecting walls and installing equipment; it’s about ensuring that every element of the data center is safeguarded from potential damage. This is where temporary surface protection comes in.

The significance of temporary surface protection extends beyond mere aesthetics. While a scratch or dent might seem superficial, it can lead to more substantial issues down the line. For instance, a damaged floor in a server room can create uneven surfaces, leading to unstable equipment placement that causes equipment malfunctions and even failures. This leads to costly repairs down the road. Furthermore, damaged surfaces can compromise the environmental controls within the data center, such as temperature and humidity levels, which are critical for the safe operation of sensitive equipment.

Finally, data centers are subject to stringent industry regulations. Any damage to surfaces during construction can result in non-compliance, leading to delays in project completion and financial penalties. By prioritizing site protection, construction teams can ensure that they meet these regulatory requirements and maintain the project timeline.

Cost Implications Of Surface Protection In Data Centers

The cost of surface protection in data centers is multifaceted. On one hand, there is the initial cost of purchasing and installing protective materials. On the other hand, there are the proven savings that come from preventing damage and avoiding costly repairs or replacements. When viewed through this lens, the expenditure on temporary surface protection becomes a cost-effective strategy in the long run. By safeguarding surfaces, construction teams mitigate the risk of damage that could lead to unexpected expenses and project delays.

Consider the cost of repairing a damaged raised floor system, which is commonly used in data centers to manage airflow and cable management. Replacing even a small section of this flooring is expensive, not to mention the labor costs associated with the repair. Additionally, any downtime required to complete these repairs can result in lost revenue, particularly if the data center is already operational. By protecting these surfaces from the outset, such costly disruptions for the construction team and client can be avoided entirely.

Meanwhile, the reputational cost of surface damage should not be underestimated. Data centers are often built for high-profile clients who expect the highest standards of quality and reliability. Visible damage to surfaces can create a negative perception of the construction team’s attention to detail and overall competence. This can impact future business opportunities and client relationships. In contrast, a pristine data center with well-maintained surfaces demonstrates a commitment to quality and professionalism, enhancing the construction team’s reputation and helping to secure future projects.

Protecting Sensitive Equipment And Infrastructure

Data centers house some of the most sensitive and expensive equipment in the world. Servers, cooling systems, power distribution units (PDUs), and networking hardware are just a few examples of the critical infrastructure that needs to be protected. During the construction phase, these components are particularly vulnerable to damage from dust, debris, and physical impacts. Implementing the correct temporary surface protection measures is essential to safeguard this equipment and ensure its longevity and performance.

One of the primary concerns during data center construction is dust and debris. These particles infiltrate sensitive equipment and cause malfunctions or failures. To combat this, construction teams should use protective coverings and barriers to shield equipment from airborne contaminants.

Physical impacts are another significant risk during data center construction. Construction traffic can easily lead to accidental impacts and damage. Protecting surfaces with durable materials can help to prevent damage from these incidents. Additionally, clearly marking pathways and designating specific areas for equipment storage can reduce the likelihood of accidental collisions and enhance overall safety on the jobsite.

Key Surfaces To Protect On A Data Center Jobsite

1. Raised Access Flooring

Installed early for underfloor cabling and airflow. These panels are expensive, fragile, and easily chipped, scratched, or knocked out of alignment.

2. Painted Drywall & Server Room Walls

High-traffic areas with tight turns. Ladders, carts, and equipment can quickly leave behind scuffs, gouges, and dirty marks.

3. Doors & Door Frames

From fire-rated doors to main corridor frames, these see constant wear and tear. Edge chips and dents are especially common in loading zones and equipment paths.

4. Glass Walls & Partitions

Often used in admin areas. Easily scratched or shattered during finishing work or equipment moves.

5. Concrete or Epoxy Floors

Utility and support areas may have exposed or finished floors. Without protection, they’re vulnerable to oil stains, cracks, and heavy scuffing.

6. Cooling System Components (CRAC units, ducting, etc.)

Installed mid-build and often left exposed. These systems are high-value—and high-risk—until the project is complete.

7. Server & Electrical Cabinets

Pre-installed or staged onsite, these units are easy to dent, scratch, or contaminate if not protected.

8. Finished Stairs, Elevators & Handrails

Moving heavy equipment in tight spaces? These areas need protection before the first load hits the stairs.

9. Windows & Frames

Whether from exterior crews or interior clean-up, glass and frames often get scratched by tools or adhesive residue.

10. Ceiling Tiles

Installed earlier than most realize, ceilings are often overlooked—until they’re covered in dust or cracked by shifting ladders.

Trusted Products For Data Center Protection

Start at the Perimeter:

Armour Grip-Terra Mat – Heavy-duty access mats effectively remove mud and debris from workers’ boots, preventing dirt and dust right from the start.

Control Dirt and Dust:

Armour Tak-Mat Pads – Install at every entrance to trap dust and debris before it reaches sensitive areas like raised flooring or server rooms.

Protect Doors and Openings:

Armour Door-Guards – an easy guard to slide over doors, providing high-impact protection.

Armour Foam Door Jamb Protector – Ideal for protecting door jambs against carts and jobsite traffic.

Cover Walls and Vertical Surfaces:

Armour Protection Boards (Green HD or Grey) – Durable and reusable. Armour Protection Board – Grey provides high-impact protection for general use, while Armour Protection Board – Green HD provides extreme impact resistance when it matters most.

Safeguard Floors:

Armour Protection Board – Green HD – Heavy-duty, high-performance protection for finished or exposed floors.

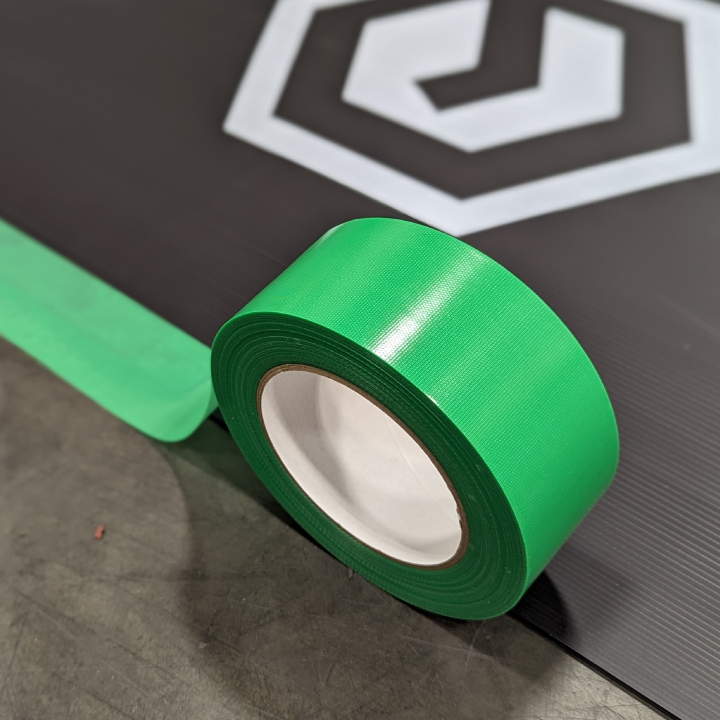

Tape That Won’t Let You Down:

Armour Pro-Clean Tape – High tack without residue. Works on painted drywall, glass, and finished surfaces without causing damage.

Manage Dust and Containment:

ZipWall Systems – Create clean, temporary barriers to isolate sensitive areas or complete work in active environments, ideal for containing dust and debris.

Conclusion

The importance of surface protection in data center projects cannot be overstated. By safeguarding key surfaces, construction teams ensure that the data center remains compliant with industry standards, free from damage, and ready for optimal operation. The financial benefits of surface protection are clear, with potential savings on repairs, replacements, and downtime far outweighing the initial costs of protective materials. Moreover, protecting surfaces helps to maintain the environmental conditions required for the safe operation of sensitive equipment, ensuring the longevity and efficiency of the data center.

- Phone: 1-866-617-8502

- Email: sales@axiomtsp.com

- Get a Quote: Request a Quote

- Order Free Samples: Request Samples